Resin Insulated Dry Type Distribution Transformer With OLTC

1. Scope of application

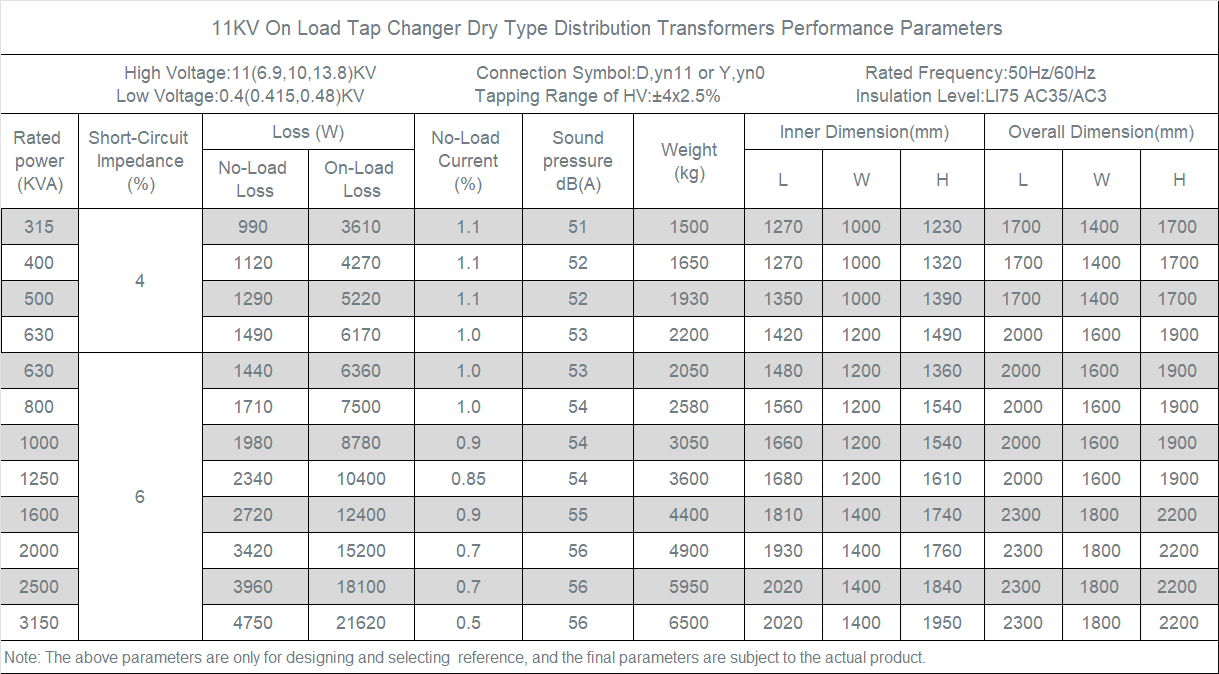

A Resin Insulated Dry Type Distribution Transformer with On-Load Tap Changer (OLTC) is a specialized type of electrical transformer designed for distribution networks. When the grid voltage fluctuates, the voltage ratio of the transformer must be adjusted in order to provide high-quality stable voltage. The dry type transformer equipped with on-load tap changer can realize the voltage adjustment with load, and can be controlled on-site or remotely through the automatic controller. Customers can choose vacuum type or air composite type on-load switch, and other on-load tap-changer types can also be configured according to requirements. The transformer are suitable for AC 50Hz/60Hz, working voltage 6KV-38.5KV and below in the power system, as a substation equipment in the field of power transmission and distribution, infrastructure, public transportation, construction and housing, industry, information technology and new energy.

2. Product standards

GB/T1094.1 GB/T1094.11 GB/T1094.12 GB/T10228 JB/T10088

GB20052 GB/T7354 JB/T3837 GB/T4208 IEC60076-11

3. Operation environment

1) Altitude: ≤1000 meters.

2) Ambient temperature: Maximum +45oC, Minimum -30oC.

3) Relative humidity: ≤90% (+25 oC).

4) Max Ground ramp degree: ≤3°.

5) Seismic level: ≤0.3m/s2 at horizontal direction and ≤0.15m/s2 at vertical direction.

6) Installation environment: No obvious and heavy pollution, no explosive and corrosive gas and dust, with good air ventilation and no severe vibration and shock.

7) If the application environment is different from the above standard conditions, please contact for customized designs.

4. Product advantages

1) Safe flame retardant, fireproof, explosion proof, pollution-free, can be directly installed in the load center.

2) Low loss, maintenance free, low comprehensive operating cost, obvious energy saving effect.

3) Good moisture proof performance, can operate normally at 100% humidity, and can be put into operation without pre-drying after decommissioning.

4) Partial discharge capacity< 5Pc, low noise, strong heat dissipation ability.

5) Strong load capacity, low product temperature rise, strong heat dissipation capacity, 140% load when forced air cooling to meet temporary emergency needs

6) Foil coils are insulated with DMD prepreg cloth to improve short circuit resistance and service life.

7) When the grid voltage fluctuates, the voltage adjustment with load can be realized, and the automatic controller can be controlled on-site or remotely.