The selection between an oil-immersed transformer and a dry-type transformer depends on several factors, including the application environment, safety requirements, maintenance needs, cost considerations, and specific project or industry standards. Here's a comparison to help you make an informed decision:

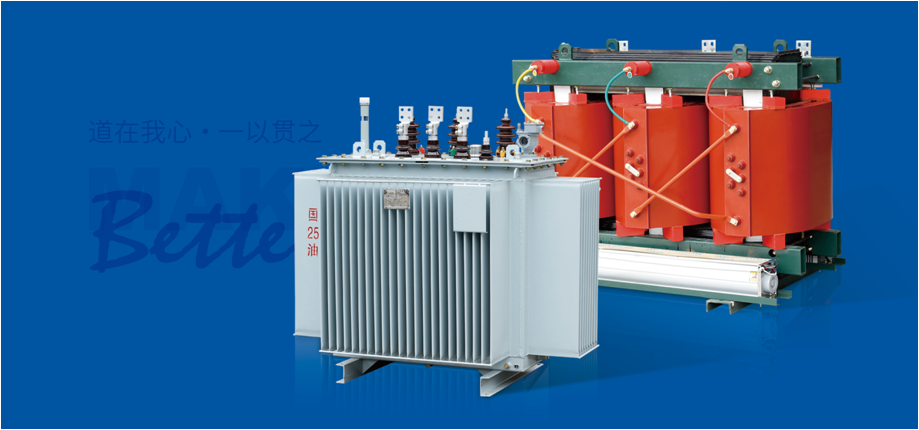

Oil-Immersed Transformers:

Cooling and Efficiency: Oil-immersed transformers use oil as a coolant and insulator, which enhances their cooling efficiency and allows them to handle higher loads. They are generally more efficient for larger power ratings.

Environment: These transformers are typically used in outdoor or environments where fire safety is less of a concern, as they pose a potential fire risk due to the flammable oil. They require a fire-resistant barrier or vault if installed indoors.

Maintenance: They need periodic testing of the oil quality, and occasional oil changes and topping up. Leaks can be an environmental concern and need prompt attention.

Noise Level: Generally quieter due to the oil acting as a sound dampener.

Cost: Can be more cost-effective for larger capacities but involve higher initial and maintenance costs due to oil handling.

Dry-Type Transformers:

Safety: Dry-type transformers do not use oil, making them safer in terms of fire hazards. They are suitable for indoor installations, especially in buildings with strict fire codes or where oil leaks could damage sensitive equipment.

Environment: Ideal for environments where environmental concerns are high, such as food processing plants, hospitals, and schools, as they don't pose risks of oil spills.

Maintenance: Require less maintenance than oil-immersed transformers since there's no oil to monitor or replace. They are also more environmentally friendly due to the lack of oil.

Temperature Sensitivity: Dry-type transformers can be more sensitive to ambient temperature and may require additional cooling systems in hot environments, affecting their efficiency and increasing installation costs.

Noise: Tend to be noisier due to the absence of oil as a sound dampener.

Capacity and Cost: Suitable for lower to medium power ratings. While they might have higher upfront costs per kVA compared to oil-immersed types for larger capacities, they can be more cost-effective for smaller applications considering the reduced maintenance and safety features.

In summary, if you're dealing with high power demands, outdoor installations, or environments where fire safety isn't a primary concern, oil-immersed transformers might be the better choice. Conversely, if your application requires indoor installation, has strict fire safety regulations, or is in an environmentally sensitive area, a dry-type transformer would likely be more appropriate.