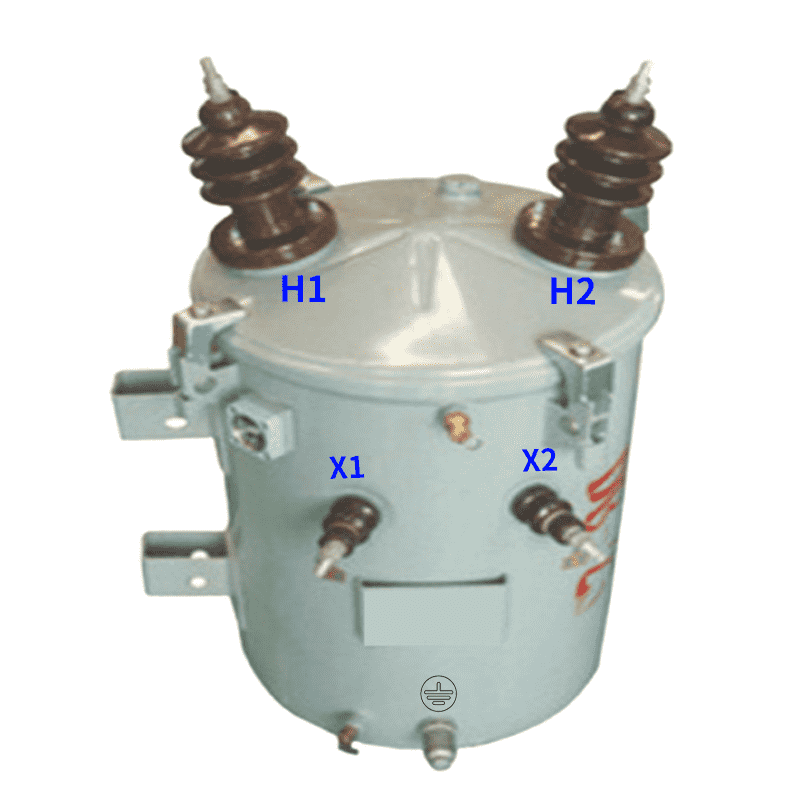

Single Phase Oil-Immersed Transformer With OCTC

1. Scope of application

A single phase oil-immersed transformer is an electrical device used primarily in power distribution systems to step up or step down voltage levels in single-phase alternating current (AC) circuits. It is designed to efficiently transfer electrical energy from one circuit to another while isolating the primary and secondary circuits, ensuring safety and compatibility between different voltage levels. The single-phase transformer can reduce the length of the low-voltage distribution line, reduce line losses, improving the power supply quality, the high efficiency and energy saving roll core structure design, the characteristics of the transformer is used in a column on suspension installations, small volume, infrastructure investment is small, reduce the radius of low voltage power supply, can reduce the low voltage line loss more than 60%. Fully sealed structure is used in transformer overload capability, high reliability of continuous running, simple maintenance, long service life.

Suitable for rural power grids, remote areas, scattered villages, agricultural production, electricity, lighting and power can also be used in railway, urban power grid column type distribution circuit on the reform.

2. Product standards

GB/T1094.1-5 GB/T1094.7 JB/T10088 GB/T6451 JB/T 10317

GB/T7595 JB/T3837 GB/T10237 IEC60076

3. Operation environment

1) Altitude: ≤1000 meters.

2) Ambient temperature: Maximum +40oC, Minimum -40oC.

3) Max outdoor wind speed: ≤45m/s.

4) Max Ground ramp degree: ≤3°.

5) Seismic level: ≤3m/s2 at horizontal direction and ≤1.5m/s2 at vertical direction.

6) Installation environment: No obvious and heavy pollution, no explosive and corrosive gas and dust, with good air ventilation and no severe vibration and shock.

7) If the application environment is different from the above standard conditions, please contact for customized designs.

4. Product advantages

1) Iron core: adopted 45° full inclined step joint process, which effectively reduces no-load loss, no-load current and core noise. The clamping and pulling plate structure makes the iron core stable and firm as a whole, thereby improving the resistance to short circuit and impact.

2) Coil: high voltage adopts cylindrical type, while low voltage adopts cylindrical type or foil type, which improves the resistance to short circuit. An oil guide structure is provided inside the winding to improve the oil flow path, thereby reducing temperature rise and increasing load capacity.

3) Oil tank: fully sealed bell structure, the reinforced iron of the oil tank adopts corrugated folding plate structure, less welds, high mechanical strength. The cooling device adopts a chip radiator, which has faster circulation speed, high heat dissipation efficiency and improved overload capacity.

4) Body: All insulating parts, winding outlets and lead welding parts have been rounded. The upper and lower parts of the device are positioned rigidly, which can ensure that the body does not shift under various transportation conditions.

5) Safety: The transformer has gas relays, pressure relief valves, oil level gauges, thermometers and moisture absorbers and other protective devices.

6) Low Cost: Using a single-phase power supply system in the power grid can save 33% to 63% of wires, It can uses 20% less iron core material and 10% less winding material than a three-phase transformer.